There is a revolution afoot in lighting. Lighting is the “low hanging fruit” in lowering commercial energy costs, reducing carbon emissions and becoming more socially responsible. Transitioning from traditional incandescent and fluorescent bulbs to LED lighting is a big part of the revolution, but so too is adding electrical control that makes sure lights are off when no one is in the vicinity.

There are a number of ways to add lighting and outlet control to a commercial building; installing retrofit occupancy or optical sensors that turn lights off automatically at the source, adding room timers or scheduling switches that cut electrical power at pre-assigned times, or by adding the ubiquitous relay panel to shut power off at the circuit level.

Lighting control panels are rapidly gaining popularity as the option of choice as location based retrofit solutions have become known to need constant maintenance and repair. Because sensors and local timers are often decentralized across the building, they are more time consuming and costly to service. Lighting control relay panels on the other hand are much more robust so they require less maintenance, and when they do need service they are centralized in the electrical control room within easy reach.

Due to this surge in popularity, manufacturers have responded with a new generation of built in control capabilities and software features that provide a much better user experience.

Traditional Relay Panel Options

Simple low voltage systems with manual controls

Early lighting control systems used relays or contactors controlled by photocells or time clocks for interior and exterior lighting in commercial, industrial and architectural applications. These early systems were difficult to program or revise to accommodate changes in business hours or work schedules. This type of control panel is self-contained in that it is a complete system as the controller and relays are both available in the same panel, but it simply isn’t very flexible. These panels are still being sold today and are a solid “low-cost” lighting control option.

Master control system controlling “simple” panels

As lighting control systems grew larger, and customers demanded more programming flexibility, expensive central control computer systems were introduced. These systems allowed flexibility to change schedules and added sensor inputs but are based on custom and often cumbersome software packages. Central control computers were installed in the main office or engineering office and connected to relay panels located throughout the facility. Making changes to the lighting schedules required someone to be certified or at least trained on working with the control software.

What these early systems lacked was remote access that would allow simple and secure access to the lighting control system from virtually anywhere, and the ability to interact with the panels from a variety of interfaces.

State of the Art in Lighting Control Panels

Self-contained web server for setup and control replaces Master control systems for small and medium sized installations.

Thanks to modern processors, today’s self-contained lighting control panels include very sophisticated controllers that rival yesterday’s master computer control platforms, but are contained in the same enclosure as the relays or controllable breakers. These state of the art lighting control panels offer advanced functionality, much simpler set-up and control, at a much more reasonable price.

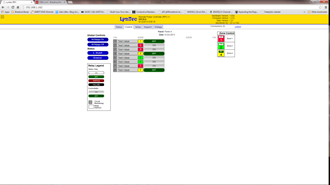

Two of the most important additions to today’s lighting control panels are imbedded web servers and Internet Protocol (IP) connectivity. IP is the highway that public Internet travels over. In addition to shopping and web surfing IP connections also make it possible to print a document to a shared office printer or send calendar appointments to screen on your refrigerator. This same functionality is now available in Intelligent Lighting Control (ILC) panels. Initial setup, control and monitoring of your ILC is done with your favorite web browser or smartphone application because the web server is built into the controller. Simply connect the controller to a network, put the controller’s IP address into your browser (Explorer, Chrome, Safari, Firefox etc.), and the graphical user interface (GUI) displays.

The graphic above is from LynTec’s RPCR relay panel GUI. Once this page loads on your browser, you have the ability to setup, control and monitor your circuit status. In controllable breaker panels, you can even monitor power usage statistics. Set up is as simple as pointing and clicking your mouse in drop down boxes. Setting up or changing schedules is a snap.

For more advanced control systems, you can also interconnect the relay panel controller to building management or master control systems that communicate in IP, RS-232, DMX 512 or sACN. Relay panels can control up to 64 relays with a single controller, and remote controlled breaker panels can operate up to 168 circuit breakers on a single controller.

With the addition of self-contained setup, control and monitoring intelligent lighting control is now a cost effective solution for projects and locations where complex system wouldn’t fit the budget.

To learn more about LynTec RPCR relay panels:

To learn more about remote controlled motorized circuit breaker panels: